Driving Efficiency and Quality in Your Organization

I can help your organization achieve operational excellence and drive continuous improvement through the implementation of Lean Six Sigma methodologies.

Tools and Techniques

By utilizing these tools and techniques, I can help your organization identify areas of inefficiency, reduce waste, improve quality, and achieve sustainable success through continuous improvement. Check out the case studies and Get in touch with me to learn how I can help your business achieve its process improvement goals.

Value Stream Mapping (VSM)

A process mapping technique used to identify areas of waste and inefficiency within a process or system.

Kaizen Events

Short-term, focused improvement events are designed to make rapid improvements to a specific process or area of the organization.

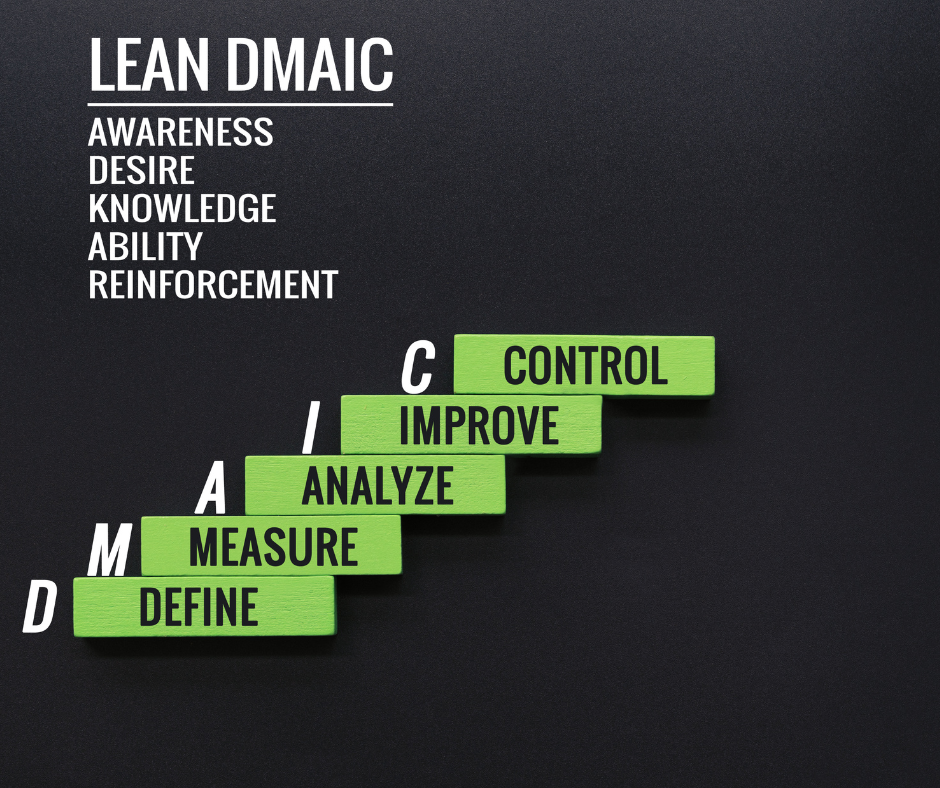

DMAIC

A structured problem-solving approach that consists of five phases: Define, Measure, Analyze, Improve, and Control.

5S

A set of workplace organization principles focused on creating a clean, organized, and efficient work environment.

FMEA

A technique used to identify potential failure modes in a process or system, and to develop preventive actions to avoid or minimize the impact of those failures.

SPC

A set of statistical techniques used to monitor and control process variation, ensuring that processes are performing within acceptable limits.

SIPOC

A tool used to understand and document the flow of a process by identifying its suppliers, inputs, process steps, outputs, and customers.

SQDCI

A continuous improvement framework consisting of five elements: Safety, Quality, Delivery, Cost, and Inventory.

GEMBA Walk

A practice of going to the “Gemba” (the place where work is done) to observe and identify opportunities for improvement.

Acquaintance with other Tools

- Kanban

- Root cause analysis

- Fishbone Diagram

- Control Charts

- Regression Analysis

- Probability distribution

- Project Charter

- Time Study

- Design of Experiments

- Descriptive analysis

- 8 Wastes

- A3- PDCA