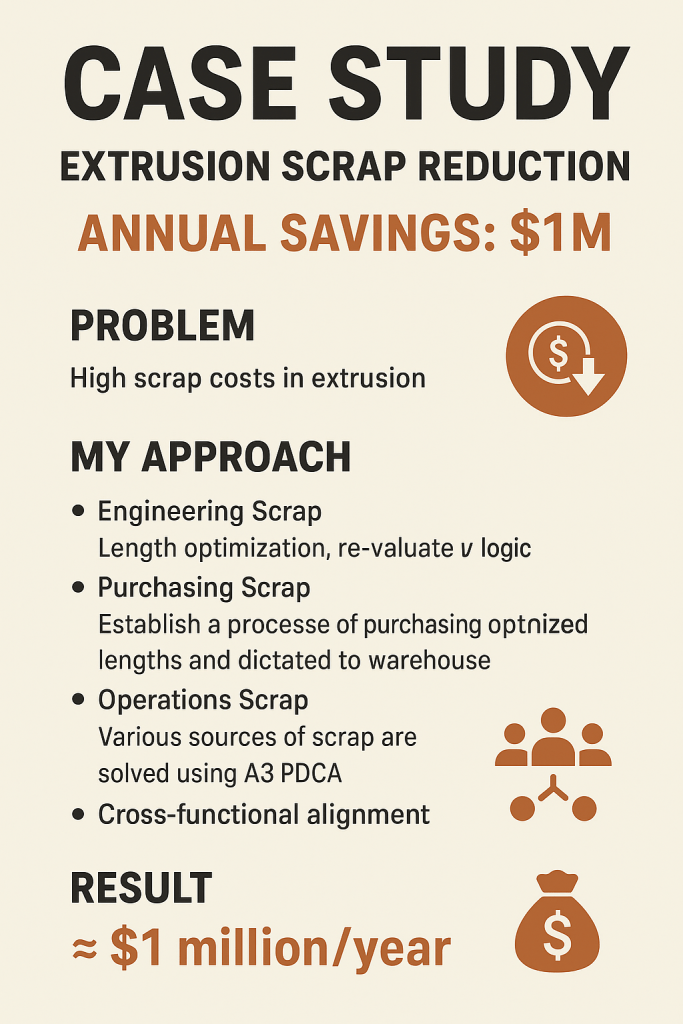

Project Overview

As the project lead, I spearheaded a company-wide extrusion scrap-reduction initiative to eliminate inefficiencies across engineering, purchasing, and operations. Extrusion scrap was one of the highest contributors to material waste and cost overruns. By addressing three major scrap sources using data-driven logic and structured continuous-improvement tools, I delivered annualized cost savings of approximately $1 million.

1. Engineering Scrap – Length Optimization Logic Redesign

Problem

The existing stock-length optimization logic used for extrusion cutting was outdated and based on assumptions that no longer matched real production behavior. This resulted in excessive waste and non-standard remnants that could not be reused effectively.

My Approach

- I performed a detailed analysis of:

- Historical cut-length data

- Mandatory process scrap allowances

- Drop usability patterns

- I re-evaluated the entire length optimization logic and developed a new calculation model that:

- Balanced cutting efficiency with reusable drop sizes

- Reduced mandatory scrap per stick

- Optimized the combination of stock lengths used in production

- I validated the new logic using simulation and pilot runs before full deployment.

Result

- Significant reduction in engineering-driven scrap

- Improved material utilization

- Standardized optimized stock-length selection across all product families

2. Purchasing Scrap – Optimized Length Procurement Process

Problem

Purchasing was ordering extrusion lengths based on vendor availability rather than true production optimization. This misalignment caused:

- High unusable drop rates

- Overstock of inefficient lengths

- Increased handling and warehouse waste

My Approach

- I created a standardized, optimized purchasing length matrix based on:

- Production demand

- Cut optimization logic

- Reusable drop strategy

- I formalized the optimized length selection process and:

- Clearly dictated purchasing rules to the procurement team

- Established a standard operating procedure (SOP) for warehouse receiving and stocking

- I aligned the Engineering, Purchasing, and Warehouse teams through structured review meetings.

Result

- Elimination of purchasing-driven scrap waste

- Reduction in non-optimal inventory

- Improved warehouse space utilization and material flow

3. Operations Scrap – A3 & PDCA-Driven Root Cause Elimination

Problem

Operational scrap was being generated due to multiple uncontrolled factors, such as:

- Handling damage

- Setup errors

- Improper storage

- Incorrect process sequencing

My Approach

- I categorized all operational scrap into defined buckets

- Performed A3 problem-solving with PDCA methodology for each major scrap driver:

- Defined the problem

- Analyzed root causes using 5-Why and Fishbone

- Implemented corrective actions

- Standardized best practices

- Key actions included:

- Improved racking and handling systems

- Standardized setup instructions

- Operator training

- Visual controls and poka-yoke solutions

Result

- Substantial reduction in floor-generated scrap

- Improved first-pass yield

- Strong operator engagement in continuous improvement

Financial Impact

- Total annualized savings: ≈ $1,000,000 USD per year

- Savings driven by:

- Material cost reduction

- Improved yield

- Reduced rework

- Lower handling and disposal costs

Leave a comment