As a senior process engineer, I had the opportunity to work on a new product line establishment project. The project involved setting up a new production line to accommodate a new product that required different processes and equipment than our existing product line. In this case study, I will detail the steps taken to establish the new product line, including conducting a mockup, working with different stakeholders, and designing and implementing the new production process.

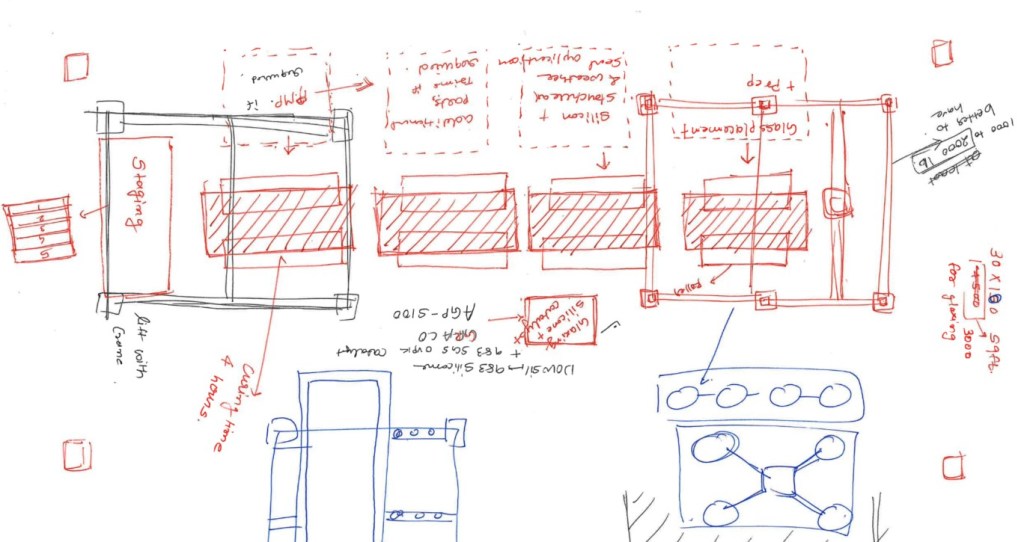

The first step in the project was to conduct a mockup with the R&D department, production, and external stakeholders. We worked together to understand the new production process and suggested the DFMA concept (design for manufacturing and assembly) to the R&D department. During this stage, we realized that the machines we had were not sufficient to handle the production process, so we had to conduct meetings with machine suppliers to find the right equipment for the job.

After selecting the necessary machinery, the next step was to create jigs and fixtures to ensure consistent and accurate production. The production process also required the involvement of our sister company for the last step. We had to ensure that the production process was seamless between the two companies.

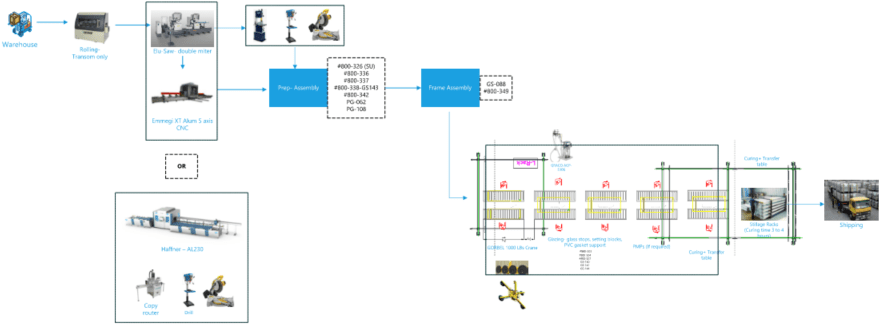

From the mockup, we learned that our existing production line could not accommodate the new product. Therefore, we had to establish a new production line specifically for this product. As the senior process engineer, I led the process mapping, communicated with different suppliers for machinery, did cost analysis, and prepared the layout, and flow of the process.

After extensive research and communication with suppliers, we identified the necessary machinery and equipment for the new production line. We created a detailed layout and flow chart of the new production process, including the placement of machinery, workstations, and material flow.

Once the design was finalized, we began the implementation process, which included sourcing and installing the necessary machinery, setting up workstations, and training employees on the new production process. We also established quality control measures and set KPIs to ensure that the new production line met the necessary standards.

The implementation process was not without its challenges. We encountered unexpected delays in the delivery of some machinery, and there were some adjustments to be made to the process flow after initial testing. However, with effective communication and problem-solving skills, we were able to overcome these challenges and successfully establish the new production line.

Overall, the establishment of the new product line was a significant project that required collaboration and communication with different stakeholders, extensive research and analysis, and effective project management skills. As the senior process engineer, I played a crucial role in the success of the project by leading the process mapping, communication with suppliers, cost analysis, and implementation of the new production process. The new production line is now operational, and we have successfully added the new product to our product line.

Leave a comment