Case Study: Kaizen Event in Window Wall Division for Documentation Streamlining and Communication Improvement

1. Problem Definition:

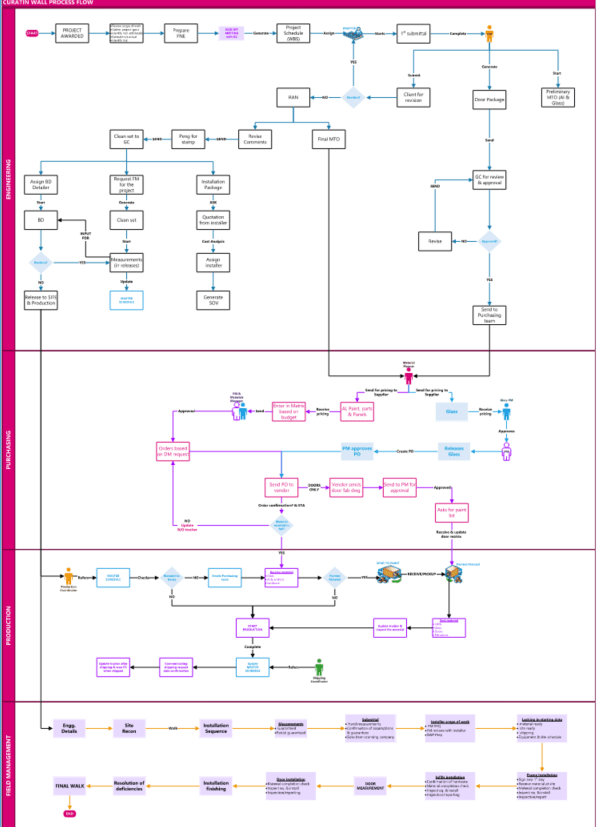

The Window Wall Division of a construction company faced challenges related to inefficiencies and miscommunication in their documentation processes. Critical documents such as breakdown packages, packing slips, and cutlists were experiencing delays and errors, leading to disruptions in the production and delivery workflow. The lack of a streamlined documentation process resulted in increased lead times, decreased customer satisfaction, and internal friction between departments.

2. Point of Cause:

The point of cause for the documentation challenges was identified at the intersection of various departments involved in the production process – design, production, quality control, and shipping. Each department had its set of requirements and expectations, leading to bottlenecks and misalignments in the flow of information. The point of handover between departments was a crucial area where documentation issues often arose.

3. Root Causes:

Upon closer examination, the root causes of the documentation challenges were identified:

- Lack of standardized documentation procedures and formats.

- Insufficient communication and collaboration between departments.

- Manual processes that were prone to errors and delays.

- Inadequate tracking mechanisms for document progress and completion.

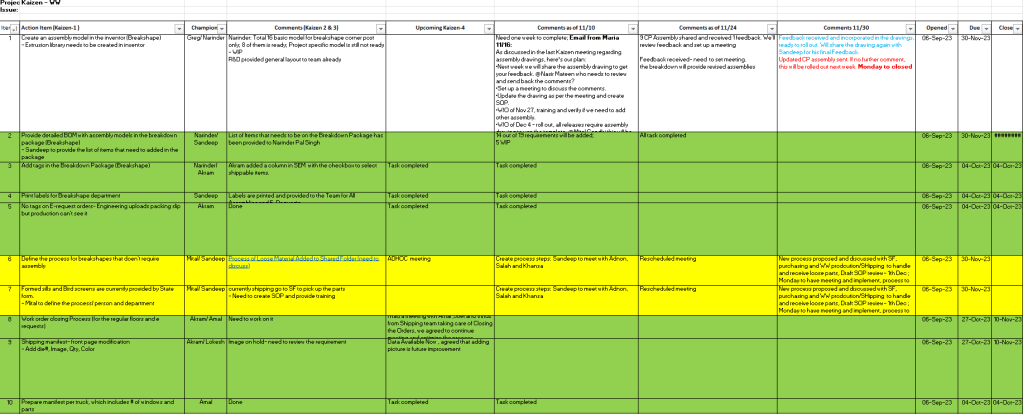

4. Action Tracker:

An action tracker was implemented to systematically address the identified root causes. Key actions included:

- Standardization: Developed standardized templates and procedures for breakdown packages, packing slips, and cutlists to ensure consistency and clarity across departments.

- Process Automation: Introduced automated tools and software to streamline the documentation process, reducing manual errors and delays.

- Cross-Functional Teams: Formed cross-functional teams representing each department to collaboratively design and implement the new documentation processes.

- Training Programs: Conducted training sessions to familiarize employees with the updated procedures and tools.

- Communication Channels: Established clear communication channels between departments to facilitate quick and accurate information exchange.

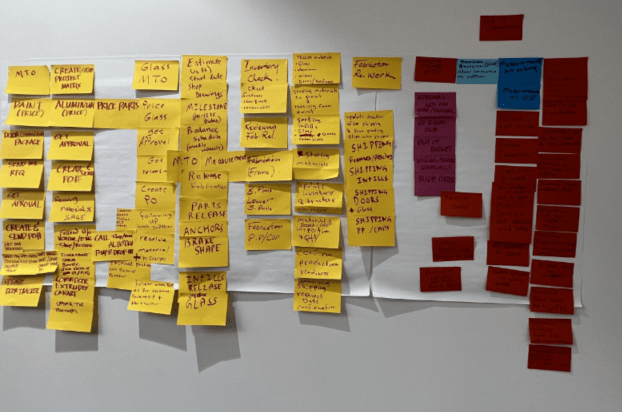

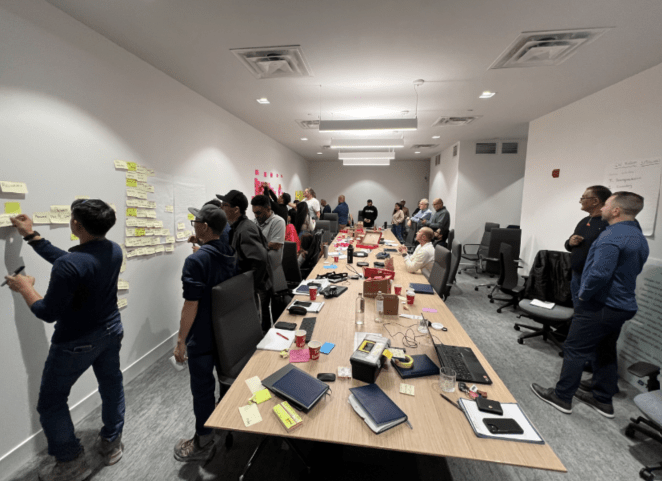

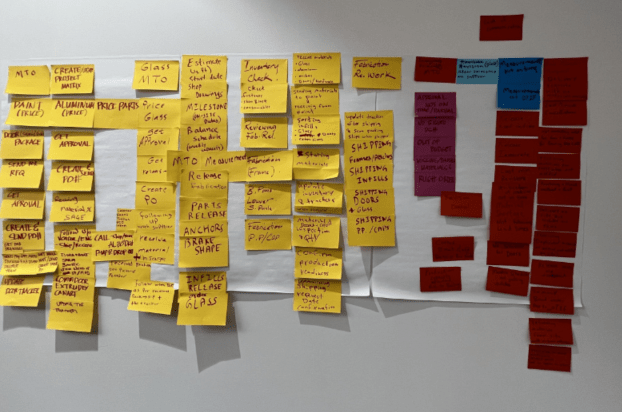

5. Series of Kaizen Meetings:

A series of Kaizen meetings were conducted to ensure the successful implementation of the proposed changes:

- Kaizen Event Kickoff: Introduced the objectives of the Kaizen event and outlined the significance of the documentation streamlining initiative.

- Current State Analysis: Discussed the current challenges in documentation processes, encouraging team members to share insights and experiences.

- Root Cause Identification: Facilitated brainstorming sessions to identify the root causes of documentation inefficiencies and miscommunication.

- Action Planning: Collaboratively developed an action plan, assigning responsibilities and timelines for each improvement initiative.

- Implementation Checkpoints: Held regular follow-up meetings to track the progress of action items, address challenges, and ensure that the new processes were being effectively adopted.

- Continuous Improvement: Encouraged an ongoing culture of continuous improvement, where feedback from employees was welcomed, and adjustments to the processes were made as necessary.

Results:

The Kaizen event resulted in significant improvements in the Window Wall Division’s documentation processes:

- Reduced Lead Times: Standardized procedures and automation led to a substantial reduction in lead times for breakdown packages, packing slips, and cutlists.

- Enhanced Accuracy: Automation and standardized templates significantly reduced errors in documentation.

- Improved Communication: The establishment of clear communication channels fostered better collaboration between departments.

- Increased Customer Satisfaction: The streamlined documentation process contributed to on-time deliveries and improved overall customer satisfaction.

Key Takeaways:

This Kaizen event exemplifies the power of continuous improvement in streamlining processes, enhancing communication, and fostering collaboration between departments. The systematic approach to problem definition, root cause analysis, action planning, and ongoing improvement highlights the effectiveness of the Kaizen methodology in addressing complex organizational challenges. The lessons learned from this event can serve as a blueprint for future improvement initiatives across the organization.