Introduction: As a Process Engineer in a manufacturing company, I was tasked with improving the production process and increasing efficiency in our assembly line. After researching various methodologies, I decided to implement the Kanban system, a lean manufacturing technique that helps improve production flow by reducing waste and improving communication.

Project Goals: The primary goal of the Kanban project was to optimize the production process, reduce lead times, and minimize inventory levels. The project aimed to achieve the following objectives:

- Improve production flow and increase throughput

- Reduce inventory levels and eliminate waste

- Enhance communication and collaboration between teams

- Increase the visibility of the production process

Project Scope: The Kanban project was implemented in the assembly line of a manufacturing plant, which produced railing sections for high-rise buildings. The project involved the following steps:

- Analyzing the current production process and identifying the inefficiencies

- Defining the value stream and creating a Kanban board

- Training the production team on the Kanban methodology and implementing the system

- Monitoring and optimizing the Kanban process

Project Execution: The project was executed in the following steps:

- Analyzing the current production process: We conducted a detailed analysis of the production process, identified bottlenecks and inefficiencies, and documented them. We found that there was a high level of inventory in the assembly line, which led to excess lead times, increased work in progress, and reduced throughput.

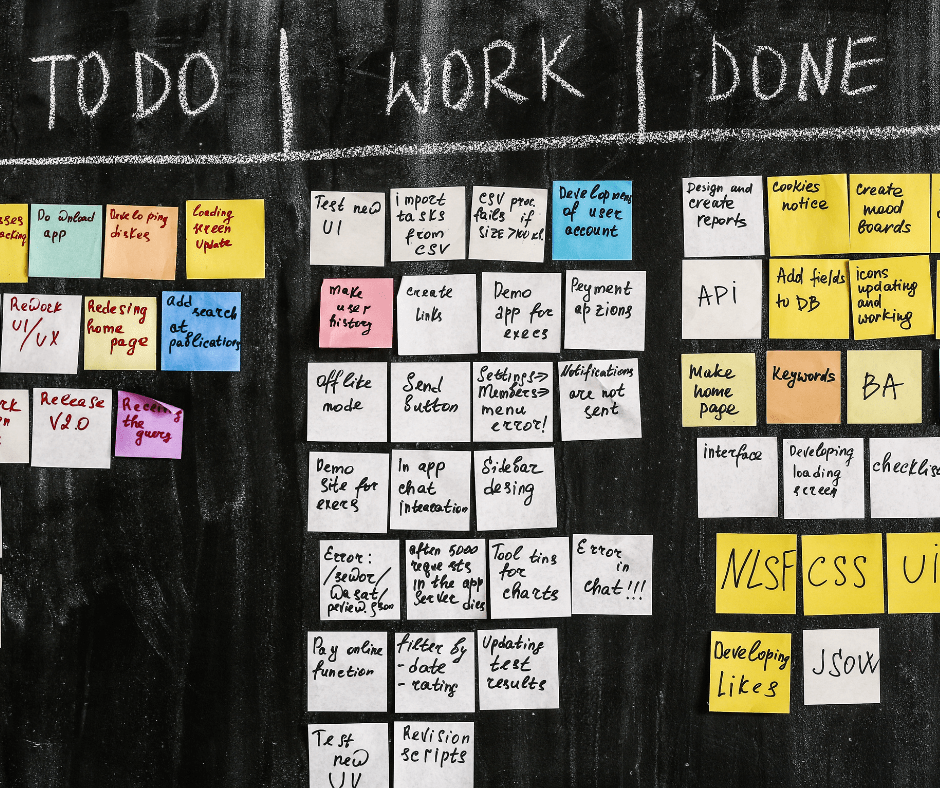

- Defining the value stream and creating a Kanban board: Based on the analysis, we created a value stream map, which helped us identify the steps that added value and the ones that did not. We then designed a Kanban board, which had columns for each step in the production process. The board had cards that represented the work that needed to be done and provided a visual representation of the workflow.

- Training the production team on the Kanban methodology and implementing the system: We provided training to the production team on the Kanban methodology and how it could be implemented in the assembly line. We then implemented the system by placing the Kanban board at a strategic location in the assembly line, and the team started using it to manage their work.

- Monitoring and optimizing the Kanban process: We closely monitored the Kanban process and collected data to evaluate its effectiveness. We identified areas for improvement and made necessary changes to optimize the process continually.

Results: The implementation of the Kanban system had several benefits, including:

- Improved production flow and increased throughput: The Kanban system helped us reduce lead times and eliminate waste, leading to an increase in throughput.

- Reduced inventory levels and eliminated waste: The system helped us reduce inventory levels and eliminate waste, leading to cost savings.

- Enhanced communication and collaboration between teams: The Kanban board provided a visual representation of the workflow, which improved communication and collaboration between teams.

- Increased visibility of the production process: The Kanban system provided real-time visibility into the production process, enabling us to identify and resolve issues quickly.

Conclusion: The Kanban project was successful and helped us optimize the production process, reduce inventory levels, and eliminate waste. The project had a positive impact on the company’s bottom line and improved the team’s productivity and morale. We plan to continue using the Kanban system in other company areas to further improve our production processes.

Leave a comment