Value Stream Mapping (VSM) is a process analysis tool used to understand and improve the flow of materials and information within a manufacturing process. As a Process Engineer, I carried out a time study as a part of the VSM in the Patio Door department. The purpose of the time study was to gather accurate data on the current manufacturing process and to identify areas of improvement to increase efficiency and reduce waste. In this case study, I will provide a brief overview of the Patio Door manufacturing process, as well as a detailed explanation of the VSM and time study methodology.

Patio Door Manufacturing Process:

The Patio Door manufacturing process begins with the creation of the profile, which is made by rolling together material, interior extrusion, and exterior extrusion. The profile then moves to the fabrication center, where it is cut and machined into either a frame or sash profile. Both profiles are then crimped, assembled on separate lines, and then undergo glazing. Finally, the frame and sash are assembled together, followed by testing, packing, and shipping.

Value Stream Mapping:

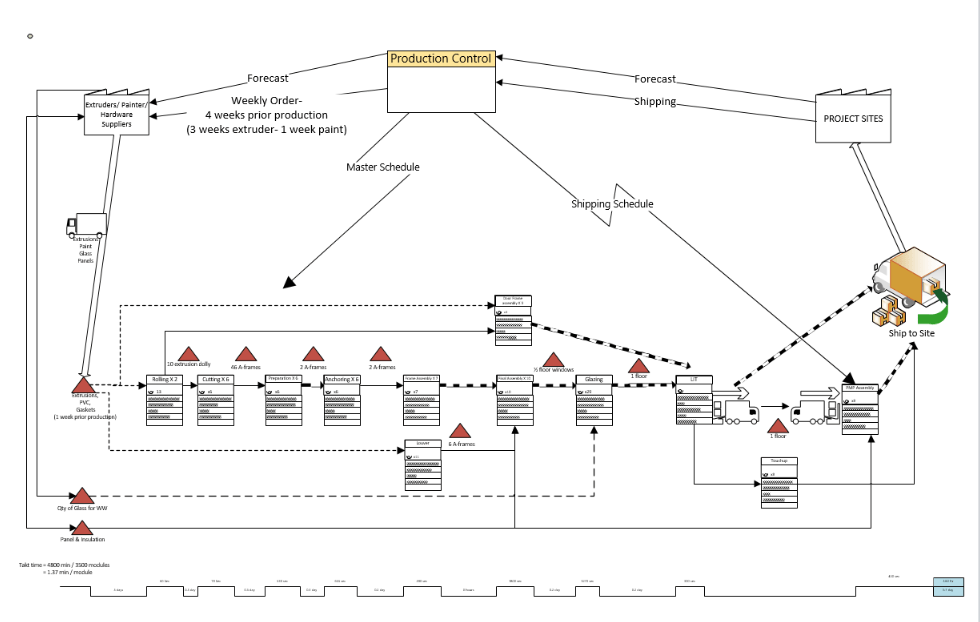

The VSM methodology involves creating a visual representation of the current process, including all the necessary activities, information flows, and material flows, from the receipt of raw materials to the delivery of the finished product to the customer. During the VSM, I gathered data on the process, including process times, queue times, and wait times, to identify bottlenecks and areas of waste. This data was then used to create a map of the current process, which was used to identify areas of improvement.

Time Study:

As part of the VSM, I carried out a time study to gather accurate data on the process times, queue times, and wait times within the Patio Door manufacturing process. The time study was conducted using a stopwatch and recorded every step of the process, including the time it took for each activity, as well as any wait times. The data gathered from the time study was used to create a detailed representation of the current process, including process times, queue times, and wait times.

Results:

The results of the VSM and time study showed that there were areas of improvement within the Patio Door manufacturing process. These areas of improvement were then prioritized, and recommendations were made to reduce waste and increase efficiency. As a result of the VSM and time study, the Patio Door manufacturing process was optimized, and the overall efficiency of the process was increased.

Conclusion:

In conclusion, the VSM and time study carried out in the Patio Door department was a valuable tool for identifying areas of improvement within the manufacturing process. The results of the VSM and time study provided a clear understanding of the current process and allowed for the identification of areas of improvement, leading to increased efficiency and reduced waste. The methodology and tools used in the VSM and time study can be applied to other manufacturing processes, and can be an effective tool for improving overall efficiency and reducing waste.