As a process engineer, I carried out a Gemba Walk in the window wall manufacturing department. Gemba Walk is a lean management technique where you go to the actual place of work to observe and understand the current processes, identify areas for improvement and eliminate waste.

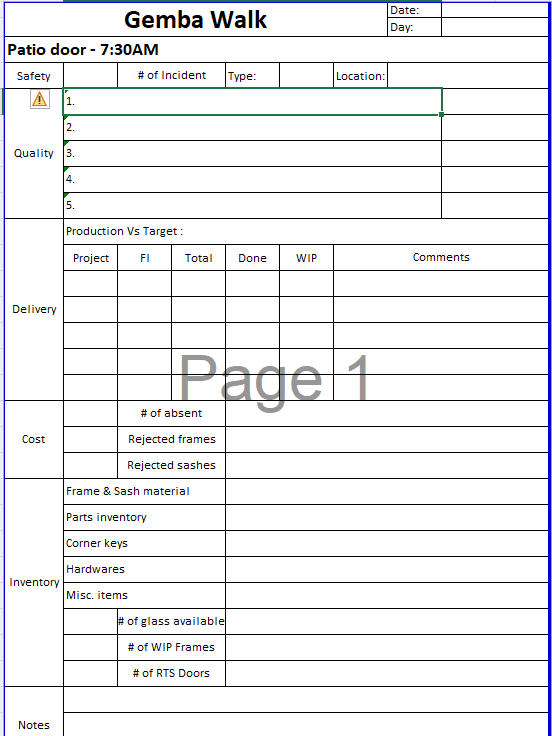

I started by creating a checklist of areas to observe and focus on during the Gemba Walk, such as the flow of materials, quality of work, and utilization of equipment. This allowed me to have a structured approach to the observation process and make the most of my time on the shop floor.

Next, I went to the actual production floor and observed each process in detail, starting from the incoming material to the final shipping of the product. I paid close attention to the flow of materials and information, the quality of work being performed, and the utilization of equipment and manpower.

I took notes and pictures to document the current processes and later analyzed them to identify areas of improvement. I found several areas where the process was not efficient and created a list of recommendations for improvement. Some of the areas where improvements were needed were:

- Redesigning the layout of the production floor to eliminate bottlenecks and improve the flow of materials

- Improving the communication between departments to ensure that everyone is on the same page and that information is flowing smoothly

- Standardizing work procedures to ensure consistency in the quality of work being performed

- Optimizing equipment utilization to reduce idle time and increase productivity

After presenting my findings and recommendations to the management, I worked with the production team to implement the improvements and monitor the results. The changes resulted in a significant improvement in the overall efficiency of the patio door manufacturing process and increased production output.

In conclusion, the Gemba Walk was a valuable tool for me to understand the current processes and identify areas for improvement in the window wall manufacturing department. By working with the production team, we were able to improve the overall efficiency and increase production output, which resulted in a significant improvement in the company’s bottom line.Top of Form

Leave a comment